Laser Cutting

Price 150 INR/ Square Foot

MOQ : 100 Square Foots

Laser Cutting Specification

- Working Area

- 1500 x 3000 mm

- Service Duration

- As required

- Supported File Formats

- DXF, DWG, AI, PLT

- Max Sheet Weight

- 750 kg

- Type of Machine

- CNC Laser Cutting Machine

- Material

- Stainless Steel, Mild Steel, Aluminum, Copper

- Cooling System

- Water cooled

- Max Cutting Speed

- Up to 40 m/min

- Cutting Thickness

- Upto 16 mm

- Cutting Accuracy

- ±0.1 mm

- Usage/Application

- Laser Cutting

- Automation Grade

- Automatic

- Laser Power Available

- 1 kW to 6 kW

Laser Cutting Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 5000 Square Foots Per Month

- Delivery Time

- 7-10 Days

About Laser Cutting

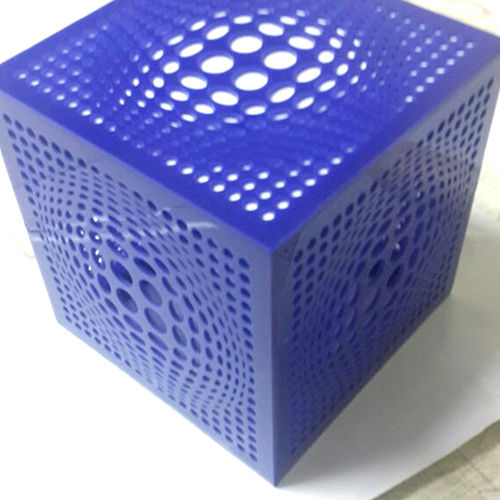

Laser Cutting

Being quality oriented organization; we are offering services such as Acrylic Laser Cutting Service. We have hired pool of industry professionals who are well versed in offering these services in the most effective manner. These services are at par with the international quality standard and have been appreciated for its excellent quality and high demand among o0ur customer base. We promise that the offered range of the services would not only fulfill all your expectations but would even go beyond them.

Features:

- Accomplished by the industry experts

- 24 x 7 customer care facility

- Improves the quality of these laser tools

Application Area:

- Used n the laser cutting industry

Exceptional Speed and Accuracy

This CNC laser cutting machine delivers reliable precision, maintaining 0.1 mm cutting accuracy even at speeds up to 40 m/min. Its automation grade ensures minimized human error and enhanced productivity, making it ideal for industries requiring both speed and consistency.

Versatile Material Handling

Designed to process a range of metals including stainless steel, mild steel, aluminum, and copper, it can handle sheets up to 16 mm thick and a maximum weight of 750 kg. This versatility makes it suitable for fabricators, manufacturers, and service providers working with diverse project requirements.

User-Friendly Automation and File Support

With automatic operation and support for popular file formats such as DXF, DWG, AI, and PLT, this machine streamlines workflow. Operators can quickly load files and set jobs, optimizing work schedules and reducing setup times in busy manufacturing environments.

FAQs of Laser Cutting:

Q: How does the CNC laser cutting machine ensure precise and consistent cuts?

A: The machine uses advanced control systems to achieve a cutting accuracy of 0.1 mm. Its rigid frame, stable water-cooling, and precise motion mechanics allow for reliably sharp and clean cuts, regardless of the metal being processed.Q: What types of materials can be cut, and what is the maximum thickness?

A: This laser cutter is engineered for stainless steel, mild steel, aluminum, and copper. It can handle material thicknesses of up to 16 mm, making it versatile for various industrial applications.Q: When should I consider using a laser cutting service with this machine?

A: Consider using this service when you require intricate profiles, rapid turnaround, or work with high-strength metals up to 16 mm thick, especially in manufacturing, fabrication, or prototyping scenarios.Q: Where can the machine be used, and who benefits from its capabilities?

A: This equipment is suitable for factories, workshops, and large-scale manufacturing in India. Both manufacturers and metal service providers benefit from its high efficiency and flexibility in handling different project demands.Q: What is the process for submitting design files, and which formats are supported?

A: Design files can be provided in DXF, DWG, AI, or PLT formats. Simply upload or transfer your file to the machines control system, set the cutting parameters, and initiate the automatic operation.Q: How does water-cooling enhance the performance of this laser cutting machine?

A: The water-cooling system keeps both the laser source and critical components at optimal temperatures during operation. This ensures reliable performance during intensive cutting tasks and extends machine lifespan.Q: What benefits does automation provide in this CNC laser cutting machine?

A: Automation offers reduced manual intervention, increased consistency, faster job setup, and improved safety. This leads to higher throughput, reduced errors, and significant savings in labor costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Acrylic Laser Cutting Category

"Our office hours are from 9:30 AM to 6:30 PM, Monday to Saturday."

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese