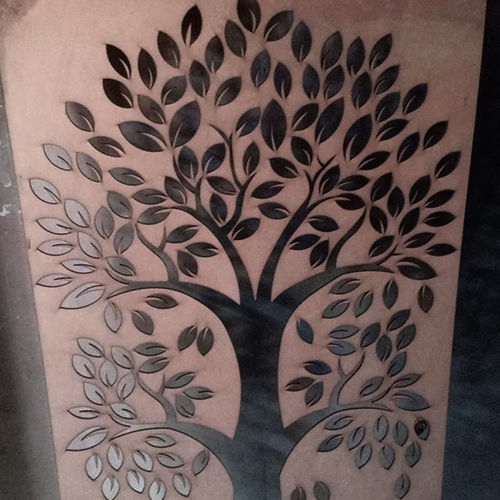

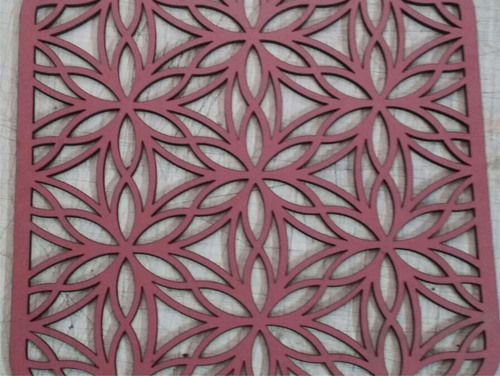

MDF Cutting Engraving Work

MDF Cutting Engraving Work Specification

- Size

- Custom Sizes Available

- Application

- Decorative Panels, Signage, Art Displays, Interior Design

- Shape

- Any Shape Possible As Per Design

- Customization

- Fully Customized Designs Accepted

- Material

- MDF (Medium Density Fibreboard)

- Technique

- Laser Cutting & Engraving

- Surface Treatment

- Engraved & Cut As Per Design

- Usage

- Interior Decoration, Shop Displays, Branding, Wall Art

- Engraving Depth

- Variable As Per Design

- Finish

- Smooth, Can Be Painted Or Laminated

- Design Type

- Custom/As Per Requirement

- Thickness

- Available in multiple thicknesses (as per requirement)

- Color Options

- Natural, Customized Colors Available

- Eco-Friendly

- Yes, Uses E1 Grade MDF Upon Request

- Edge Type

- Precision Cut, No Rough Edges

MDF Cutting Engraving Work Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 5000 Square Foots Per Month

- Delivery Time

- 7-10 Days

About MDF Cutting Engraving Work

MDF Cutting Engraving Work Services

Counted among the top utilities in the market, the following MDF Cutting Engraving Work is made by using qualitative required components with the help of latest methodology. It is widely utilized in manufacturing industries for laser cutting on various non-metal surfaces. This item is demanded in the market because of its good quality, hassle free performance, tough structure and highly durable in nature. The entire range of provided items are tested on the various quality parameters before dispatching them from our premises. MDF Cutting Engraving Work is delivered by us at a reasonable price rate within the promised time period.

Specification

|

Cutting Type |

CNC engraving |

|

Service Type |

In House |

|

Size |

Bed Size 5feet x 10feet |

|

Machine Used |

CNC Router |

|

Materials |

Plain MDF |

|

Price |

Per square feet |

|

Surface Treatment |

Engraving |

|

Color |

Any |

|

Dimension |

as per client choice |

|

Dust Proof |

NO |

|

Brand |

Motif Graphics |

Precision and Quality in Every Detail

We guarantee exacting standards with our laser cutting & engraving process. Our team produces bespoke pieces featuring smooth edges, variable depths, and customizable colors. Each project is crafted to suit your aesthetic and functional needs, whether for retail environments, modern interiors, or striking wall art. Explore feasible materials, adaptable thicknesses, and endless design possibilities.

Comprehensive Customization for Unique Projects

Clients benefit from our ability to turn any concept into reality. With a broad selection of finishes, shapes, and color customizations, our service addresses diverse applications from signage to decorative panels. We accept fully personalized designs and cater to branding requirements, ensuring your installation stands out and expresses your identity.

Eco-Conscious Manufacturing with Flexible Options

Sustainability is central to our process. We use medium density fibreboard sourced responsibly and offer E1 grade MDF on request for heightened eco-safety. From material selection to final treatment, our workflows emphasize environmental mindfulness. Each piece is designed for both durability and minimal impact, supporting creative interiors and responsible sourcing.

FAQs of MDF Cutting Engraving Work:

Q: How does the MDF cutting and engraving process work for custom designs?

A: Our team employs precise laser cutting and engraving to transform MDF into personalized decorative pieces. Clients share their design requirements, preferred colors, and shapes. We then select the appropriate MDF thickness, prepare digital files, and use advanced machinery to achieve smooth finishes and intricate details, ensuring every product matches your vision.Q: What color options and finishes are available for MDF artworks and panels?

A: We provide natural MDF as well as customized color finishes. Products can be painted in any shade or laminated for extra durability and style. The surface treatment can be tailored to design preferences, whether you wish for bold colors, subtle tones, or a natural wood look to enhance your application.Q: When should I choose E1 grade MDF for my project?

A: E1 grade MDF is ideal for projects requiring enhanced environmental safety, particularly in spaces where air quality or health standards matter. You may request E1 grade material at any stage, and we recommend it for installations in homes, shops, or public venues that prioritize low emission standards.Q: Where can customized MDF laser cutting and engraving be used?

A: Our services apply to a wide array of settings, including interior decoration, art displays, branding, wall art, shop signage, and decorative panels. The versatile application is suited for commercial spaces, residential environments, exhibit installations, and anywhere artistic expression or branding is needed.Q: What shapes and sizes are possible for MDF cut and engraved products?

A: We accept fully customized design files or concepts, allowing production in virtually any shape or size. Whether you require intricate geometries, large-format panels, or small signage, our manufacturing capabilities accommodate diverse measurements and forms to fit your space or branding needs.Q: How does using laser cutting ensure precision and quality in MDF products?

A: Laser technology provides clean, accurate cuts and enables detailed engraving work. This method eliminates rough edges, maintains consistent depth per design, and ensures a smooth, flawless finish. Clients can trust our technique to faithfully reproduce their designs with superior craftsmanship and aesthetic appeal.Q: What are the key benefits of choosing your MDF cutting and engraving service?

A: Our service stands out for full customization, eco-friendly options, precision cutting, and variable engraving depths. We prioritize smooth finishes and accept any design, ensuring your project is unique and professionally executed. Whether you seek branding, decoration, or creative displays, we deliver quality, flexibility, and reliable customer support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese