Plywood Waterjet Cutting Services

MOQ : 100 Square Foots

Plywood Waterjet Cutting Services Specification

- Production Capacity

- High volume as per customer demand

- Maximum Sheet Size

- 1500 mm x 3000 mm

- Service Location/City

- Pan India

- Maximum Sheet Thickness

- 80 mm

- Lead Time

- 2-5 working days

- Service Type

- Plywood Waterjet Cutting Services

- Material

- Plywood

- Surface Finish

- Smooth, Burn-Free edges

- Cutting Type

- Waterjet Cutting

- Design File Format Accepted

- DXF, DWG, PDF

- Cutting Tolerance

- ±0.2 mm

- Thickness

- Customized as per requirements

- Service Mode

- Offline

- Minimum Sheet Thickness

- 1 mm

- Uses/Application

- Industrial & Commercial projects

Plywood Waterjet Cutting Services Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 5000 Square Foots Per Month

- Delivery Time

- 7-10 Days

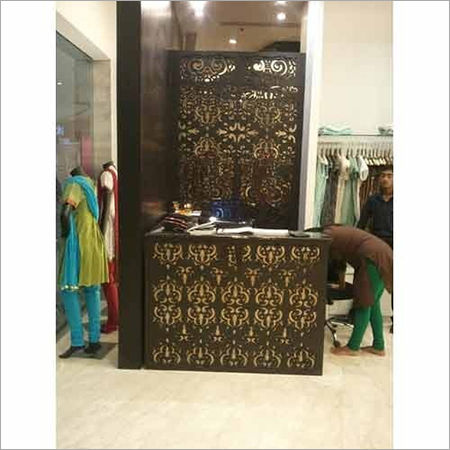

About Plywood Waterjet Cutting Services

Located at Maharashtra, Mumbai, India, we have successfully been engaged in rendering Plywood Waterjet Cutting Services. The offered services are executed under the supervision of our highly experienced and diligent professionals who work in close-coordination with clients. We ensure to provide highly efficient solutions as per exact preferences of clients. In addition to this, we use advanced cutting tools and defect free piece of plywood in order to execute these Plywood Waterjet Cutting Services with high precision.

Features:

- Provide precise cutting

- Rendered as per specification provided by clients

- Quality devoted approach

High-Precision Cutting for Versatile Applications

Our plywood waterjet cutting service offers exceptional accuracy, enabling complex and detailed cuts for a wide variety of industrial and commercial uses. The advanced process ensures burn-free, smooth edges, catering to both functional and aesthetic needs. Suitable for large projects, our facility is equipped to manage high volume orders swiftly, supporting businesses across India.

Customizable Thickness and Rapid Turnaround

Whether you require thin veneers or thick structural panels, we accommodate plywood thicknesses from 1 mm up to 80 mm. Supporting sheet sizes up to 1500 mm x 3000 mm, projects can be tailored to your unique specifications. With a rapid lead time of 25 working days, we ensure timely delivery without compromising on quality.

FAQs of Plywood Waterjet Cutting Services:

Q: How does the waterjet cutting process work for plywood?

A: The waterjet cutting process uses a high-pressure stream of water, sometimes mixed with abrasives, to accurately cut through plywood. This cold-cutting technique preserves the material integrity, producing smooth, burn-free edges and preventing warping or discoloration.Q: What types of design files are accepted for plywood waterjet cutting?

A: We accept DXF, DWG, and PDF file formats for design submissions. These formats are commonly used in CAD software and allow us to accurately translate your designs for waterjet cutting.Q: What is the typical lead time for plywood waterjet cutting projects?

A: Our standard lead time is between 2 to 5 working days, depending on the project size and complexity. High volume orders are accommodated efficiently, ensuring your deadlines are always met.Q: Where are your plywood waterjet cutting services available?

A: Our services are available pan India. We support clients across the country with quick turnaround and reliable delivery, catering to a broad range of industrial and commercial sectors.Q: What benefits does waterjet cutting offer compared to other plywood cutting methods?

A: Waterjet cutting provides precise, smooth, and burn-free edges without causing material distortion. Its suitable for intricate designs and thick or thin sheets, offering greater flexibility and superior finish compared to traditional cutting methods.Q: Can the plywood thickness be customized according to specific requirements?

A: Yes, we cater to customized thickness requirements, handling plywood sheets ranging from as thin as 1 mm to as thick as 80 mm, as per project specifications.Q: What are the ideal applications of plywood waterjet cutting services?

A: Our plywood waterjet cutting services are ideal for industrial and commercial projects that require detailed patterns, high precision, and a superior surface finishsuch as signage, furniture components, construction elements, and architectural details.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ply Laser Cutting Category

"Our office hours are from 9:30 AM to 6:30 PM, Monday to Saturday."

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese